If you work in the oil and gas, chemical, or petrochemical industry, you’ve likely encountered ferrule fittings and manifold valves. These components play crucial roles in ensuring the safe and efficient operation of process systems. In this article, we’ll cover everything you need to know about ferrule fittings and manifold valves, from their functions to their advantages.

What are Ferrule Fittings?

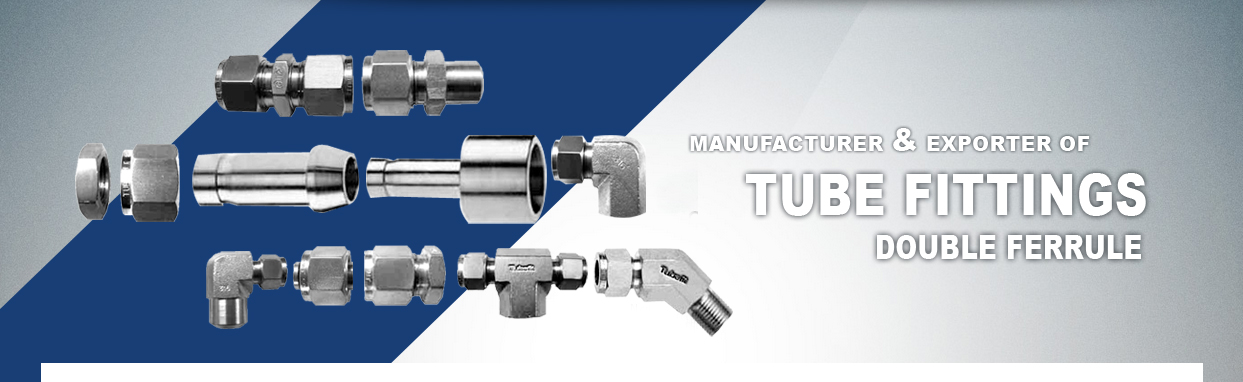

Ferrule fittings, also known as compression fittings, are used to connect and seal tubes and pipes in a process system. According to the Ferrule fittings Manufacturers, They consist of three main components: the nut, the back ferrule, and the front ferrule. The front and back ferrules are typically made of high-strength materials like stainless steel or brass, while the nut is made of softer materials like brass or aluminium.

Stainless Steel Ferrule Fittings are designed to provide a leak-proof, vibration-resistant connection that can withstand high pressure and temperature. They are also easy to install and can be disconnected and reconnected multiple times without damaging the components or the tubing. Stainless Steel Ferrule Fittings Manufacturers use it in applications that require frequent maintenance, such as instrumentation and analytical systems.

What are Manifold Valves?

Manifold valves are used to control the flow of fluids or gases in a process system. They consist of a block with multiple valves that are connected to a common inlet and outlet. Manifold valves can be either two-way or three-way, depending on the number of ports they have. They are typically made of materials like stainless steel or brass, which can withstand high pressure and temperature.

Manifold valves offer several advantages over traditional valves. They provide a compact and efficient way to control the flow of multiple fluids or gases in a single unit, reducing the need for multiple valves and piping. They also simplify the maintenance and repair process by allowing technicians to isolate and service individual components without shutting down the entire system.

What are the Advantages of Ferrule Fittings and Manifold Valves?

Ferrule fittings and manifold valves offer several advantages over traditional piping and valve systems. According to the Manifold valves Manufacturers, here are some of the key benefits:

- Leak-proof: Ferrule fittings provide a leak-proof seal that can withstand high pressure and temperature.

- Vibration-resistant: Ferrule fittings are designed to resist vibration, which reduces the risk of tubing damage and system failure.

- Easy to install: Ferrule fittings can be easily installed without specialised tools or training.

- Easy to maintain: Ferrule fittings can be disconnected and reconnected multiple times without damaging the components or the tubing.

- Compact: Manifold valves provide a compact and efficient way to control the flow of multiple fluids or gases in a single unit.

- Maintenance-friendly: Manifold valves simplify the maintenance and repair process by allowing technicians to isolate and service individual components without shutting down the entire system.

Overall, ferrule fittings and manifold valves are essential components for any process system that requires reliable and efficient fluid or gas control. By providing leak-proof, vibration-resistant, and easy-to-maintain connections, these components help ensure safe and efficient operation of your process system.