Mitsubishi’s MBR filtration product is an advanced biological membrane technology that eliminates pollutants and bacteria in water. MBR stands for Membrane BioReactor, which is an advanced method of treating wastewater and clean water, widely used in industrial and domestic applications. The Mitsubishi MBR membrane is commonly used in professional wastewater treatment systems, especially in biological membrane filtration tanks. In today’s article, SGE invites you to join us in learning more about this MBR membrane filtration technology in the electroplating wastewater treatment system. Let’s take a look.

What is electroplating wastewater?

Electroplating wastewater is a type of wastewater generated from the surface metal production and treatment process. This wastewater contains toxic substances such as heavy metals, organic and inorganic compounds, and harmful pollutants to the environment and human health.

The electroplating process involves the use of chemicals to clean and treat the metal surface, and the water used in this process is often polluted. If not treated properly, electroplating wastewater can be harmful to the environment and human health.

To treat electroplating wastewater, methods such as chemical treatment, biological treatment, physical treatment, or a combination of these methods are required to remove pollutants and meet the specified wastewater quality standards.

>> Read more: Màng lọc MBR dạng sợi rỗng

BMBR tank and its structure

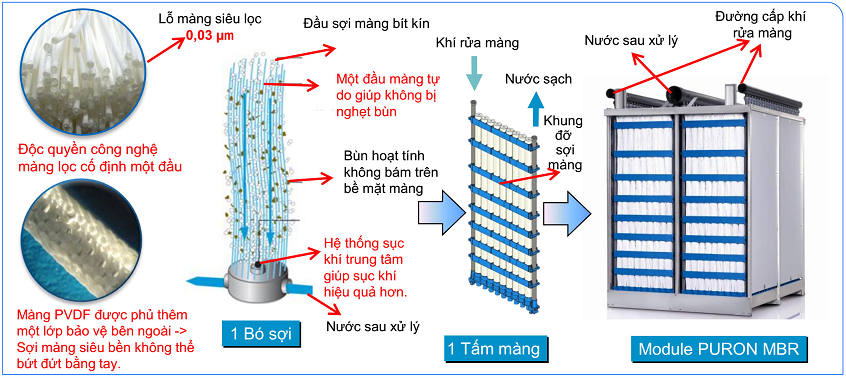

MBR tanks are made up of flat or tube-shaped hollow fibers, which can be combined with both forms to create an MBR unit. Each MBR unit consists of multiple interconnected, robust hollow fibers, each of which is a separate filtration membrane with many tiny holes on the surface to prevent waste and debris from passing through.

Currently, there are 5 common MBR membrane configurations, including hollow fibers (HF), spiral, flat sheet, box, and tubular.

A few advantages of MBR membrane filtration technology

The MBR biological membrane filtration technology has several advantages, as follows:

– Firstly, the treated water quality meets high standards and can be reused for purposes such as road washing, irrigation, etc.

– Secondly, there is no need to use a secondary settling tank like traditional activated sludge technology and other microbial technologies, saving the maximum area.

– Thirdly, it is suitable for places with complex installation terrain.

– Fourthly, it has a high degree of automation.

– Finally, it is often installed in the form of modular equipment, making it easy to install and move when needed.

The biological membrane filtration technology MBR is an efficient and reliable method for treating electroplating wastewater. If you need further support and advice, please contact us at SGE via the hotline: 0909.997.365.

>> See more: Giá thể vi sinh dạng sợi