Infusion forming is perhaps the most normally utilized strategy for creating indistinguishable plastic items in high volumes. Notwithstanding, likewise with each cycle, it is imperative to comprehend the particular plan limitations that should be clung to encourage the undeniable advantages of effectively delivering savvy, top-notch parts.

Complex Part Design

Infusion embellishment can deal with incredibly complex parts, and consistency, just as the capacity to make a huge number of for all intents and purposes indistinguishable parts. To upgrade the adequacy of high-volume infusion forming and boost the exactness and nature of your parts, key plan components ought to be considered. The Plastic Product Design should be created to amplify the productivity inborn in high-volume molding. With the right configuration, parts can be made reliably and with quality. Without a decent plan, exorbitant preparation missteps can be made.

Low Volume Creation Prospects

The uplifting news is Plunkett Associates have spent numerous years creating procedures and methods to remove a portion of the issues recognized beneath, especially for parts that would customarily be considered excessively troublesome or surprising to form. Moreover, Custom Plastic Moulding in making infusion forming definitely more practical for much lower amounts of parts than is all the more ordinarily anticipated. Utilizing half and half of the strategies, our low volume creation tooling allows us to tweak to customer/calculation/quantities. The result is a form instrument that mirrors the prerequisite and opens up an energizing choice to deliver high caliber, yet low volume segments.

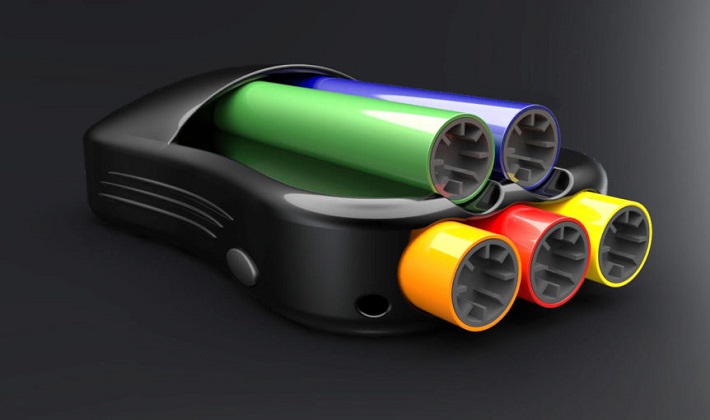

Adaptability Material And Color

Picking the correct material and shading for a task are two of the fundamental factors in making plastic parts. Because of the wide assortment of both, the prospects are nearly endless. The advances in polymers throughout the years have added to the improvement of a huge choice of tars from which to choose. It is imperative to work with an injection molder that has insight into an assortment of pitches and applications including saps that are agreeable with FDA, RoHS, REACH, and NSF. To guarantee you select the correct sap for your undertaking, remember the accompanying factors of Plastic Molding Manufacturing: sway strength, rigidity, a flexural modulus of flexibility, heat diversion, and water retention.

Part Plan Limitations

The interaction of infusion shaping methods there is a few limitations with respect to the part plan. You may have to roll out a couple of improvements to your parts so we can make them for you – or settle on an alternate assembling procedure. The main thing to acknowledge is that a form instrument is produced using two parts that need to pull separated, and the part should have the option to be delivered from the apparatus. This is straightforward, however monstrous. It has a wide range of repercussions down the line as far as apparatus plan.

To genuinely profit by all the preferences recorded over, it’s significant that makers search out experienced complex infusion disintegrates who realize how to amplify the effectiveness and defeat any plan or cycle gives that may emerge for Plastic Product Design.

Related: Perks Of Choosing Plastic Injection Moulding In Commercial Area