3D printing – or additive manufacturing – has become an important part of the production processes in many industries. In your company too – if not today, then tomorrow. There is no getting around this technology, and it is no coincidence that the Gartner Institute predicts:

The three most important questions when using 3D printing.

1. What are the benefits of 3D printing for my company?

3D printing can offer a number of business benefits. What is important, however, is to clearly define the specific benefits that you are looking for. Is your priority in reducing costs in research and development, product development, or manufacturing? Would you like to generate more sales by bringing products to market faster or creating completely new product lines that are only possible through additive manufacturing? When you properly understand your business priorities, you can choose the right 3D printing approach for your needs now and in the future.VideoJet Inkjet Printer also Provide wide range of Printing Related Provlem.

2. What is the total cost of ownership?

When evaluating different approaches – competing providers, different printing technologies and internal versus external solutions – consider the following cost factors:

- Acquisition cost of the printer itself

- Consumption costs (including materials and consumables such as printheads)

- Warranty costs

- Labor costs , particularly in relation to post-processing parts

- Costs for the premises including furnishings (3D printers often have to meet certain requirements in terms of water installation, ventilation or other things)

3. How does the solution fit into my long-term additive manufacturing strategy?

3D printing represents the future strategy of every manufacturer. At the beginning of this innovation curve, additive manufacturing changes the processes in the manufacture of a wide variety of products. The global consulting firm Ernst & Young categorizes companies in terms of their additive manufacturing strategy into four levels of maturity .

The 4 levels of maturity in the additive manufacturing strategy.

I.

Level 1: No experience

At this first stage, business leaders usually have little or no knowledge of how 3D printing can help make the business more productive or successful.

II

Stage 2: experimentation and testing

At this level, managers such as department heads or production managers start investing in this technology, testing it and understanding it. The company has not yet developed any structured processes for the application of 3D printing.

III

Level 3: Deployment in individual departments / areas

There is a clear direction here for the application of 3D printing in a particular department. There are measurable results within certain departments or application areas; there is a desire to extend the utility to other parts of the business.

IV

Level 4: Strategic application in the company

At this level there is full support for the technology at the management level, the applications of 3D printing are embedded in the corporate strategy.

Regardless of where your company is in this maturity model:

You need a 3D printing solution provider who is by your side every step of the way. We believe in a collaborative, customer-centric approach where we first understand your priorities, challenges, needs and desired outcomes. With our innovative 3D systems solutions, we offer you the broadest portfolio in the industry, including software, hardware, materials and professional services. And we deliver solutions that are precisely tailored to your special requirements.

Which technology is the right one?

No single 3D printing technology can do everything equally well – and certainly not everything. There are many different 3D printing technologies with their own strengths and weaknesses that make them great for some applications and not at all suitable for others. Each technology processes unique materials – from elastomers to plastics to metals and others – and uses different methods to make parts. Some manufacture robust, production-ready parts that can withstand years of demanding operation, while others manufacture parts that are intended for short-term use. Some are making large parts at the same time, while others are designed to print one or a few parts as quickly as possible.

Instead of describing the individual technologies in detail, our guide will help you identify the right technology for your requirements and goals. There is always one rule of thumb: Beware of vendors who make sweeping claims that their printing technology meets all of your needs.

Make or Buy – internal, external or both?

The key question is: What kind of applications do you have today – and in the future? Do you usually need to print the same type of parts or does it differ from project to project? So z. B. stainless steel parts today and flexible parts tomorrow? One of the first decisions you need to make is whether to print in-house, outsource, or take a hybrid approach.

3D printing in-house

If all or most of your 3D printed parts are similar in terms of material and performance characteristics, it makes most sense to have your own 3D printers optimized for that application.

3D printing outsourced

If you work with different materials and the performance characteristics of your 3D printed parts have to meet different requirements, an external solution is probably the right choice – keyword: On Demand Manufacturing.

Hybrid 3D printing

A combined approach with in-house printing for your most common applications and on-demand manufacturing for everything else combines the time advantages of the internal solution with the flexibility of the external solution.

Overview 3D printer portfolio 3D Systems.

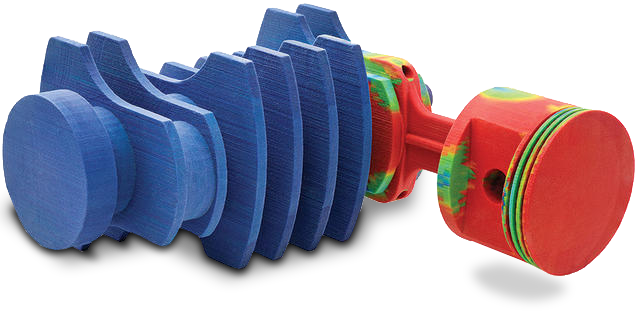

Direct Metal Printer (DMP)

No compromises in the design and production of metal parts for products, components and tools. The advantages are weight reduction, improved functionality and simplified assemblies. Save time, money and part weight with an integrated precision metal manufacturing solution from our comprehensive range.

Stereolithography (SLA)

The measure of all things when it comes to accuracy and precision, these 3D printers offer an expanded range of plastic materials and operate with minimal waste. This ensures the most productive and reliable operation even with large construction volumes.

Selective laser sintering (SLS)

The SLS printers from 3D Systems are suitable for prototypes and finished parts. They support a wide range of nylon materials that meet almost any requirement: high durability, heat resistance, elongation, fire resistance, certified Class VI for medical use, chemical resistance and ISO 10993 for food contact.

Figure 4

The first scalable, fully integrated 3D printing solution. The Figure 4 solutions deliver precise parts made from a variety of robust, producible materials that enable immediate workpiece turning without additional costs or delays in tooling. Benefit from an up to 15-fold improvement in throughput and up to 20% lower part costs.

Colorjet printer (CJP)

Suitable for prototypes through to end use. From educational purposes to the most demanding commercial applications, 3D printers of the ProJet x60 family offer unique color functions with exceptional printing speed, high efficiency and low operating costs.

Multijet printer (MJP)

This low-cost 3D precision printer series delivers high-quality and functional prototypes made of elastomer-like multi-material and wax at printing speeds up to 3 times faster, lower total cost of ownership and easier finishing.

Desktop printer

3D Systems’ 3D desktop printers are ideal for engineering, manufacturing, and jewelry applications. They are particularly suitable for small quantities, prototyping and the production of small components in a variety of high-quality materials.