We live in times where screens and displays have become an integral part of our lives. From smartphones and other consumer electronics to industrial machinery, screens are everywhere. And while they have become vital for user interaction and operational efficiency, there is one recurring issue devices with screens often face – screen damage.

Now, there can be several reasons behind a damaged or broken screen – impact, pressure, improper handling, environmental factors, and what not, and this damage needs to be addressed efficiently for smooth operations and user experience across devices. But anyone can catch cracks or damage on a screen, right? Wrong! Traditional methods for screen damage detection rely on manual checks and often fall short in terms of speed, scalability, and most importantly, accuracy. This is where AI-based automated screen damage detection systems enter the scene.

These screen damage detection tools use artificial intelligence and machine learning to identify and analyze even the subtlest signs of damage with unmatched precision. In addition to enhancing reliability and efficiency of quality control, these aid in reducing downtime and costs.

Looking to learn more about the transformative impact of AI damage detection? This blog is for you.

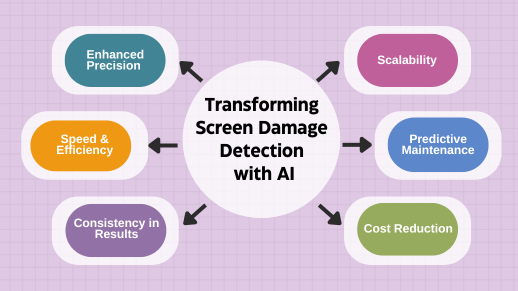

How is AI Changing the Landscape of Screen Damage Detection?

AI-powered screen damage detection does a great job combating the inefficiency of manual inspections and basic automated systems.

Enhanced Precision

Many AI algorithms are fully capable of analyzing images of screens and displays with commendable accuracy as they are trained on vast datasets of damage and undamaged screens. This makes them capable of identifying even the tiniest imperfections such as scratches, dead pixels, cracks, and other anomalies.

Speed & Efficiency

AI-powered screen damage detection systems are immensely powerful as their accuracy is backed with unparalleled speed. In a setting where thousands of screens need to be inspected every day, speed plays a crucial role, and this is where these systems are most useful.

Consistency in Results

Different humans will have varying levels of expertise and that will certainly impact the results in screen damage detection. Since AI damage detection systems provide reliable and consistent performance irrespective of the external conditions, one can stay assured that every screen or display is being subjected to the same rigorous inspection standards.

Scalability

Scaling an AI system to handle a large number of screens is much easier than scaling a team of humans (and more cost-efficient). This is an important factor particularly for companies that manufacture or refurbish electronic devices on a large scale. AI-based automated screen damage detection systems let them maintain high-quality standards even when production scales up.

Predictive Maintenance

The best thing about AI-powered screen damage detection is it doesn’t only detect existing damage, but also predicts potential issues based on patterns and trends in screen wear and tear. This feature alone empowers companies to significantly extend the lifespan of their screens by allowing them to implement proactive maintenance measures.

Cost Reduction

All the above features combined contribute to a reduction in costs associated with repairs, returns, and warranty claims.

Key Features of Automated Screen Damage Detection

Automated screen damage detection systems generally come equipped with a wealth of features that enhance their utility and effectiveness. These include:

- Automated screen damage detection systems use high-resolution cameras to capture detailed images of screens to ensure that even the smallest defects are visible and can be accurately analyzed by the AI algorithms.

- The core of any AI-powered system is the algorithms it operates on. Automated screen damage detection systems use algorithms trained on extensive datasets which result in high accuracy in the results.

- The standout feature of an automated detection system is its ability to generate results in real time. This allows for instant corrective actions and minimizes the chances of defective products.

- They can detect different kinds of screen defects including scratches, cracks, dead pixels, discoloration, and touch sensitivity issues to ensure that no defect goes unnoticed.

- These systems typically have cross-device compatibility, and thus, can be programmed to detect defects in pretty much all kinds of screens and displays, and still return highly accurate results.

Behind the Screen Damage Detection Technology: How It Works

Screen damage detection systems bring sophisticated hardware and advanced software together to deliver results with unmatched precision and efficiency. The process begins with high-resolution cameras capturing the images of the display in a way that they cover the entire screen. These images are then preprocessed for quality enhancement and making them suitable for analysis. Next up is feature extraction where specific characteristics such as edges, color patterns, and more are identified to lay the groundwork for accurate screen damage detection. After successful feature extraction, the machine learning algorithms do their job by analyzing the images and identifying the defects. These defects are then classified further to help understand the severity and type of damage. In some specific cases, the AI-powered damage detection system can be integrated with quality control systems and MESs to improve the overall efficiency of the quality control process. AI damage detection systems go beyond detecting defects to predict potential issues and allow manufacturers to implement preventive measures. When you have the results in the end, you will be able to make informed decisions about what to do next!

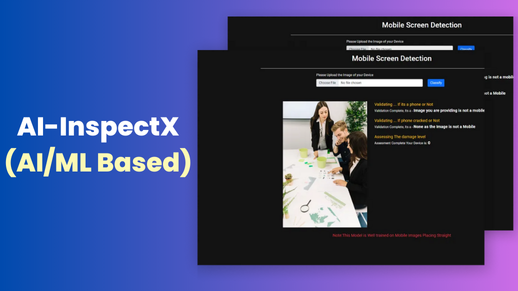

The Spotlight on AI-InspectX

Seasia Infotech’s proprietary screen damage detection tool, AI-InspectX, is a state-of-the-art tool that promises remarkable accuracy and continuous improvement. In addition to all the basic features of a reliable AI-powered screen damage detection tool, AI-InspectX can also assist with phone make and model detection where needed. And this is not all. We have numbers that back our claims. Since our next-gen machine learning model based on CNNs using TensorFlow was deployed across different warehouses for a client, they’ve been able to automate 80% of the inventory processing and reduce 90% of overall processing time.

Want to learn more? Here’s a deep dive into the technical workings of the damage detection process.

AI-InspectX uses CCD cameras and advanced image processing to capture the images from different angles, and then convert them into HSI color format for accurate analysis. It uses the Nanonets API for precise crack detection. Trained on over 8000 images from more than 200 devices, the screen damage detection tool promises high precision and accuracy, every single time!

Our expert AI developers can also customize AI-InspectX to suit your specific requirements and use cases when you contact us.

What Will You Achieve Using Screen Cracks Detection Systems?

Here’s the simple answer: enhanced product quality, increased efficiency and productivity, cost savings, minimized downtime, data-driven insights, competitive advantage, improved customer satisfaction, and the list goes on.

But if you are curious how your industry can benefit from an AI-powered screen damage detection software, you may find this table helpful.

| Industry | Achievements Using Screen Cracks Detection Systems |

| Consumer Electronics | Improve product quality by ensuring screens without defects reach consumers. Minimize financial impact of defective product returns. Consistently deliver high-quality products, building brand loyalty and trust. |

| Automotive Industry | Ensure defect-free in-car displays. Maintain high standards without slowing down production. Predict potential screen failures and address them proactively. |

| Healthcare Sector | Maintain high-quality screens on diagnostic devices for accurate readings. Prevent malfunctions in critical medical devices. Schedule maintenance and repairs, minimizing downtime. |

| Manufacturing and Industrial Equipment | Ensure defect-free display screens in industrial equipment. Implement rigorous quality control measures. Detect and address defects early, minimizing replacement and repair costs. |

| Retail and Commercial Displays | Ensure flawless screens for displays and advertising. Provide a seamless and visually pleasing experience. Quickly identify and replace defective screens. |

| Aerospace and Defense | Maintain integrity of screens in critical equipment. Ensure display systems are fully operational. Use predictive analytics for maintenance planning. |

| Education and Training | Ensure perfect condition of interactive whiteboards, tablets, and monitors. Quickly detect and replace damaged screens. Implement preventive maintenance measures. |

| Screen Damage Insurance | Accurate damage assessment. Streamlined claims processing. Reduced fraudulent claims. |

Future Prospects and Developments

What’s next for AI in mobile damage detection and how it will continue to evolve.

AI-powered mobile damage detection is set to advance enormously over the next few years. From improvements in accuracy through more sophisticated algorithms to integration of multi-sensor data, these systems will become more cost-effective and accessible. As we progress, the number of devices that have screens and displays will also grow, and AI-powered screen damage detection systems are not going to lose their relevance anytime soon.

How Does Seasia Come into Play for Screen Damage Detection?

Seasia Infotech has a demonstrated history of developing world-class software solutions for clients across all kinds of industries. Our proprietary AI damage detection tool, AI-InspectX is already being used worldwide in manufacturing processes and warehouses in numerous ways!

If you want to leverage our expertise to build a customized solution for your need, we are just one call away!

Feel free to get in touch now.

Source Link: https://shorturl.at/KGC1n